In PackBenefit, S.L., we continue to focus on innovation and continuous improvement of our production processes to offer sustainable packaging solutions of the highest quality. In this line, we have implemented an Artificial Vision system in our laminating machines, which allows us to significantly improve the quality of our products and optimize the efficiency in the manufacture of our compostable trays.

Project Objectives

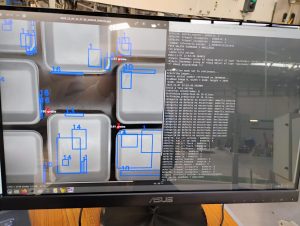

The main objective of this project is to automate the quality control in the laminating process through the use of advanced Machine Vision technologies. Thanks to the installation of high resolution cameras and specialized software, we are able to identify defects in real time, minimizing material waste and ensuring that each package meets the highest quality standards.

Benefits and Impact

The implementation of this technology has brought a number of key benefits to our production:

Financial Support

This project has been possible thanks to the support of a public grant, aimed at financing investment projects. The funding received has been key to the acquisition of automated inspection equipment, state-of-the-art cameras and advanced image analysis software, which have transformed the way we work. The equipment has been non-repayable, co-financed by the European Union through the European Regional Development Fund (ERDF), with the support of the Ministry of Finance, the Institute for Business Competitiveness and the Regional Government of Castilla y León, with the aim of promoting the development of competitiveness and the consolidation of the business fabric of companies in the community, through the promotion of investment.

Our Commitment to Industry 4.0

With this initiative, PackBenefit takes a further step in the integration of digital technologies in its production process, aligning itself with the principles of Industry 4.0. The implementation of Machine Vision allows us to move towards a more efficient, sustainable and technologically advanced production, ensuring that our packaging continues to be a reference in the sector.

Contribution to Sustainability

Our company is committed to developing packaging solutions that reduce environmental impact and food waste, and promote the circular economy. The trays we manufacture at PackBenefit are a real and sustainable alternative to conventional plastic packaging. With this new system, we not only improve product quality and safety, but also reduce resource waste and optimize the use of biodegradable materials.

Acknowledgement

From PackBenefit, S.L., we would like to thank the support of [name of the granting agency], which has made possible the implementation of this innovative project. We will continue working to implement new technologies and continue leading the sustainable packaging sector.